- This topic is empty.

-

AuthorPosts

-

2025-11-13 at 1:55 pm #7756

In modern mechanical engineering, precision gear manufacturing is a cornerstone of industries ranging from automotive to industrial machinery. Among the most effective methods for producing high-quality gears is worm gear hobbing, a process that ensures accuracy, efficiency, and long-lasting performance.

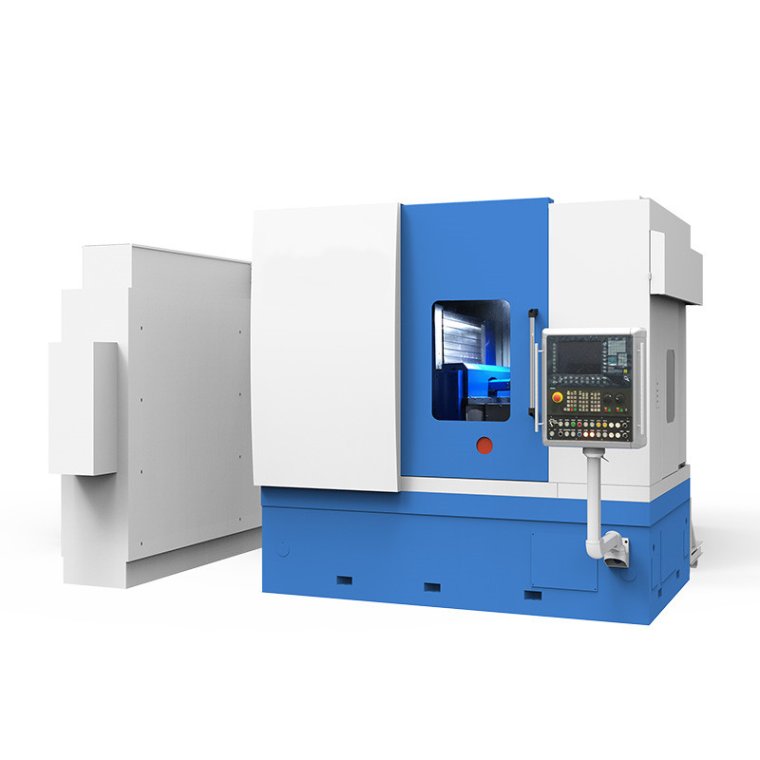

GLT Machinery (GLTM/GLT), a leading Chinese manufacturer of CNC hobbing machines, specializes in producing high-speed, high-efficiency CNC gear hobbing machines. With a focus on rigidity, reliability, and precision, GLT provides tailored gear manufacturing solutions for automotive, motorcycle, reducers, synchronous pulleys, and pump industries. Their expertise demonstrates the transformative advantages of employing worm gear hobbing in modern production lines.

Here are the top benefits of using worm gear hobbing for precision gear manufacturing.

1. Exceptional Precision and Accuracy

Worm gear hobbing is renowned for producing gears with high dimensional accuracy and smooth surface finishes. This method allows precise control over tooth profile, pitch, and depth, which is critical for applications that demand reliable and noise-free performance.

-

GLT Machinery’s CNC hobbing machines are engineered to maintain tight tolerances, ensuring gears meet strict industrial standards.

-

High-precision worm gears improve the efficiency and durability of mechanical systems in vehicles, pumps, and industrial machinery.

2. High Efficiency and Productivity

Compared to traditional gear-cutting methods, worm gear hobbing offers faster production rates with fewer setups. The continuous cutting action of the hob reduces downtime and increases throughput, making it ideal for large-scale or repetitive production.

-

GLT Machinery designs machines with high-speed operation and automated processes, maximizing productivity without sacrificing quality.

-

Efficient production reduces operational costs and accelerates delivery timelines for manufacturers.

3. Versatility for Different Gear Types

Worm gear hobbing is highly versatile and can produce a variety of gears, including worm gears, helical gears, and spur gears, with consistent quality.

-

This flexibility allows manufacturers to meet diverse client requirements without investing in multiple specialized machines.

-

GLT Machinery’s hobbing systems support a wide range of gear sizes and specifications, making them suitable for industries such as automotive, reducers, and synchronous pulleys.

4. Enhanced Gear Strength and Durability

The precise cutting action of worm gear hobbing produces gears with uniform tooth profiles, reducing stress concentrations and wear. This results in stronger, longer-lasting gears that can withstand heavy loads and demanding operational conditions.

-

GLT Machinery ensures that its CNC hobbing machines maintain rigidity and cutting consistency, which contributes to the durability and performance of the final gear.

-

Durable gears are essential in high-performance applications such as automotive transmissions, pumps, and industrial reducers.

5. Reduced Noise and Vibration

Well-manufactured worm gears produced through hobbing exhibit smoother meshing and minimal backlash, leading to quieter and more stable operation.

-

GLT Machinery’s high-precision hobbing machines help reduce vibration and mechanical noise, enhancing the overall efficiency and comfort of mechanical systems.

-

This benefit is especially valuable in automotive and precision machinery applications where noise reduction is critical.

6. Cost-Effectiveness for Long-Term Production

Although investing in CNC worm gear hobbing machines requires initial capital, the long-term benefits make it cost-effective:

-

Reduced scrap rates due to high precision

-

Increased productivity and faster production cycles

-

Fewer machine setups and labor requirements

GLT Machinery’s advanced hobbing machines provide manufacturers with reliable, high-quality solutions that pay off through improved efficiency and reduced operational costs.

Conclusion

Worm gear hobbing is a highly effective method for precision gear manufacturing, offering superior accuracy, high efficiency, versatility, durability, and reduced noise. Manufacturers looking to produce high-performance gears for automotive, industrial, or machinery applications can greatly benefit from incorporating this process.

GLT Machinery (GLTM/GLT) exemplifies excellence in this field, providing high-speed, high-rigidity CNC hobbing machines tailored to the unique requirements of modern gear production. By leveraging worm gear hobbing technology, businesses can achieve precision, reliability, and cost-effective production, ensuring their mechanical systems perform optimally for years to come.

http://www.gltmachinery.com

Wuxi General Machinery Co., Ltd. (GLTM / GLT) -

-

AuthorPosts

- You must be logged in to reply to this topic.